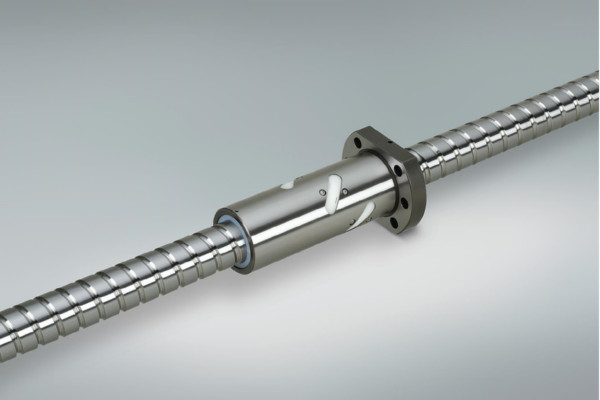

NSK unveils new-generation DIN-standard ball screws

NSK used the recent EMO 2017 exhibition in Hanover, Germany as the launch platform for a number of innovations designed to enhance machine tool performance. Among the major introductions was a new generation of DIN-standard ball screws. The high-speed, low-noise ball screws not only overcome the specific challenges of European machine tool applications, but also conform to DIN 69051 (ISO 3408) with regard to both dimensional and tolerance classes.

Manufactured in shaft diameters from 32 to 63 mm, and with leads from 10 to 40 mm, the new high-speed, low-noise ball screws for European machine tool applications offer a speed factor of 160,000 dn. This performance level means they can be used without restriction for high-speed machining applications where very accurate positioning is also required.

The smooth running properties of the new ball screws also set a new benchmark, establishing optimal pre-conditions for incurring the least possible vibrations in the linear system, while simultaneously reducing noise levels. Among the main contributors to this favourable combination of characteristics are the ball deflectors, which were newly developed to suit the new series.

NSK has been developing ball screws for machine tools since 1960. Today, the product portfolio is wide-ranging, offering shaft diameters from 4 to 200 mm, as well as numerous types for specific requirements such as extreme low noise, short strokes and maximum positioning accuracy.

About NSK

Established 100 years ago, NSK (Nippon Seiko Kabushiki Kaisha) is a Japanese-listed company that has evolved from a regional ball bearing supplier to a roller bearing specialist and automotive supplier with a global market presence. Today, NSK employs more than 31,500 employees in 30 countries. As per March 2017 NSK achieved a turnover of 950 billion Yen. This result has been driven by ever-increasing investment in research & development, enabling the company to continuously improve the quality of its products and services. This investment supports NSK’s objective of “No. 1 in Total Quality”. In addition to a complete rolling bearing portfolio, NSK develops and manufactures precision components and mechatronic products, as well as systems and components for the automotive industry, including wheel bearing units and electric power-steering systems.

In 1963, NSK’s first European subsidiary, Düsseldorf, Germany, was opened and in 1976, the first European production facility in Peterlee, England. Today, NSK Europe supports pan-European sales with production locations in England, Poland and Germany, logistics centres in the Netherlands, Germany and England and technology centres in Germany, England and Poland. In 1990, NSK purchased the UPI Group including the renowned European bearing manufacturer RHP, with its factory in Newark (UK). Additionally, NSK has developed a comprehensive network of authorised sales distributors. NSK Europe is divided into application-based business divisions: Industry rolling bearing technologies & linear and precision technology (EIBU) as well as bearing modules and steering systems for the automotive industry (EABU & ESBU). In this organisation, NSK Europe’s 3,600 employees achieved a turnover of over 1,000 million Euros as per March 2017. For more information, visit www.nskeurope.com

Source:bearing-news

【 Go Back 】 | 【 Print 】 | 【 Close this window 】